From the biggest brands relaunching 3D shoes to generativeAI moving into three dimensions and cities investing in advanced manufacturing districts, 2024 accelerated a new manufacturing paradigm.

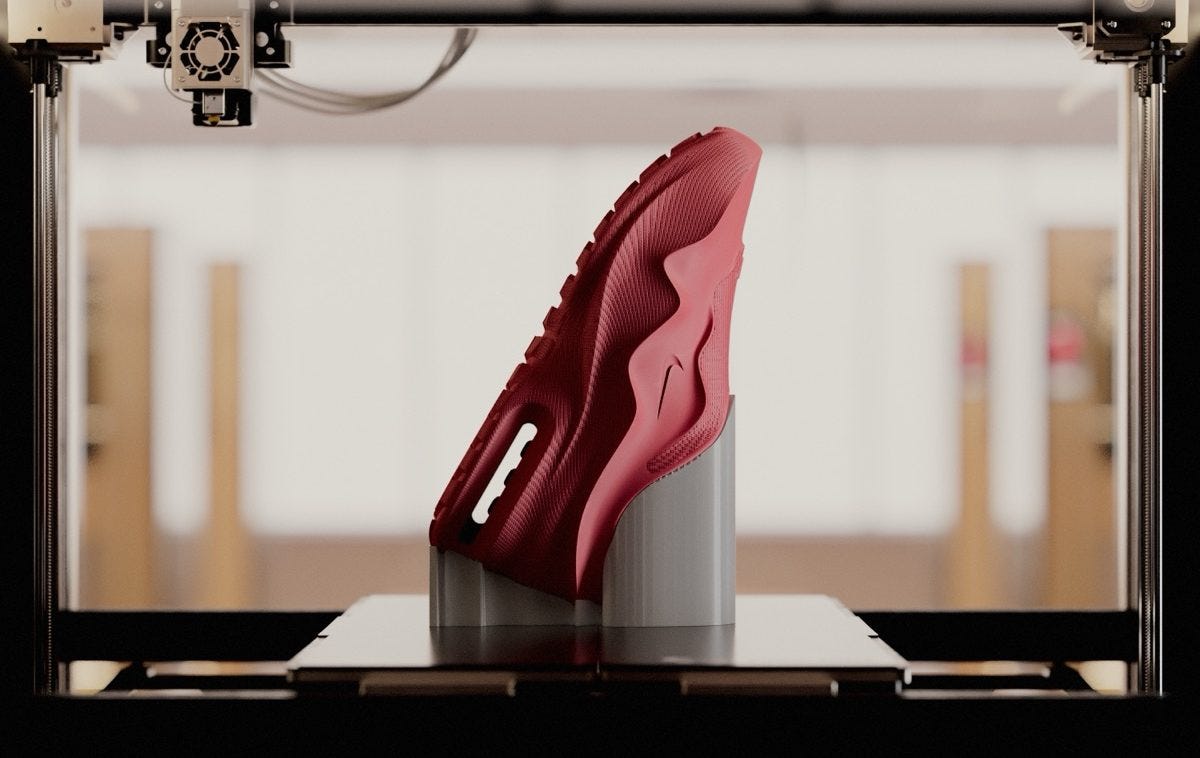

2024 was the biggest year for 3D printed footwear since Futurecraft launched in 2017, but this time it wasn’t just NIKE and Adidas leading the way. From Puma to Steve Madden, amid extreme supply chain volatility and a lost decade of innovation, footwear brands from fashion to performance are signaling a new age for 3D footwear.

Part of this renaissance is undoubtedly due to the leaps in genAI over the past 18 months. GenAI has evolved from prompt-based to multimodal-based applications, delivering more control to the creator while rapidly dissolving the barriers between 2D and 3D. While this has shrunk the gap between digital design and physical manufacturing considerably, expertise is still required for bringing 3D design over into physical manufacturing. This is one reason why 3D concept shoes are more plentiful than ever, but scaled production still ephemeral.

The maturation of dynamic geometric (FRep) CAD modeling, multimodal genAI, and 3D printing technologies are leading to a new language for manufacturing that will define this century.

- Function-representation (implicit) modeling and openVDB-based computational design allows for highly complex 3D assets to be designed at the atomic level without relying on manual or procedural workflows.

- Multimodal GenAI and accompanying advances in computer vision over the past year essentially allow computers to independently draw, see, and learn. This enables the rapid training and improvement of the “instructions” and command language required for f-rep modeling.

- Improvements in cost, materials, and coloring across powder, resin, and filament-based printing over 2025 deliver competitive manufacturing technologies that are uniquely positioned to translate advancements in design technology into immediate parts and products. In 2025 costs are set to fall by another 30% alongside the introduction of multi-color printing.

Taken together these advances allow for a designer to go from an image or sketch to a functional product in hand without any intermediary, directly translating design intent into engineered and manufacturable products. While that in and of itself is a massive disruption to a chain of intermediaries, a completely digital toolchain like this with a multimodal design engine enables the integration of massive amounts of data in real-time into the design and manufacturing chain. For designers this will feel like going from the telegram straight to wireless internet.

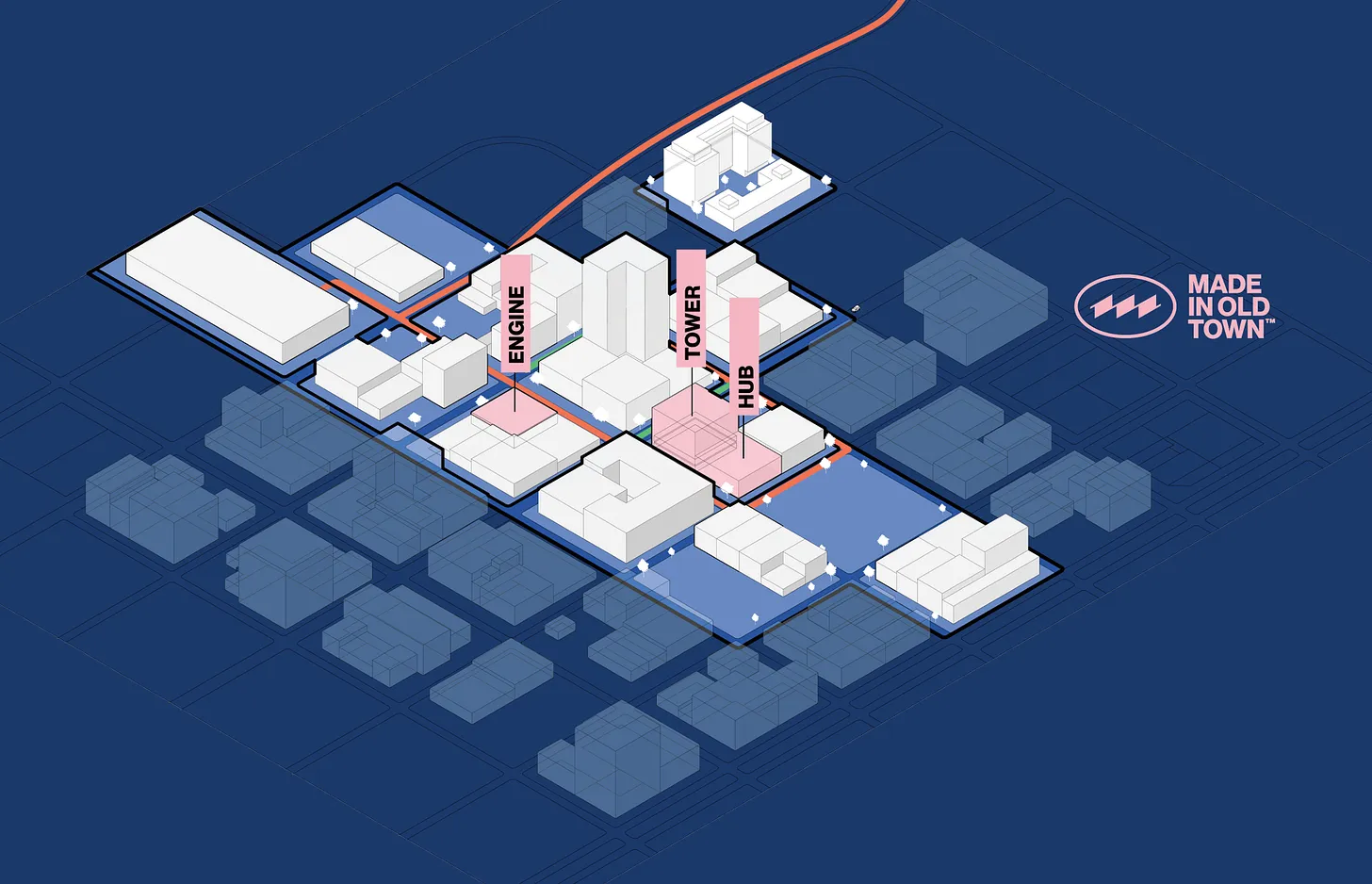

This wave of generative manufacturing automation comes at a time of focused re-industrialization for the U.S. and Europe. As manufacturing increasingly moved to lower-cost Asian markets over the last four decades we lost an astonishing amount of human experience and technical infrastructure, not just for manufacturing but for manufacturing innovation. The Made in Old Town initiative is our answer to how we can bring supply chains back to the U.S., accelerating manufacturing innovation domestically while reinvigorating our urban cores and the future of the American city. I see a unique opportunity to leverage the weight of American brands and our technological lead across additive and genAI to pioneer this post-industrial supply chain.